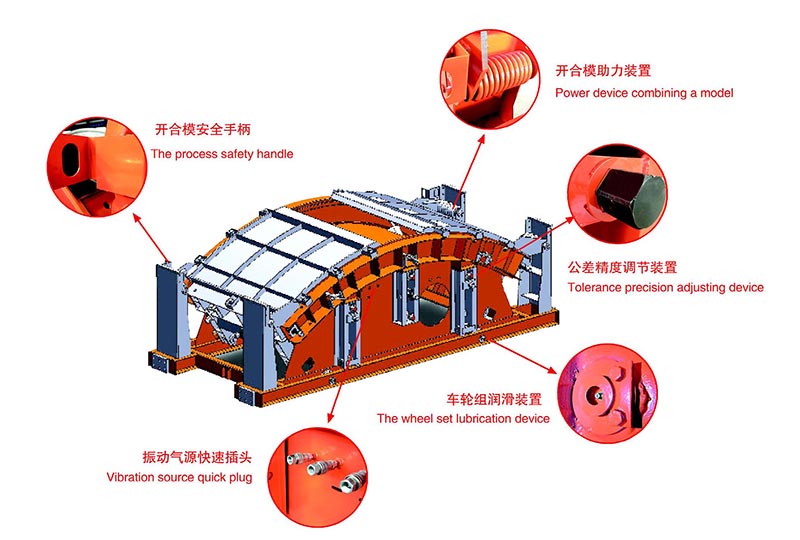

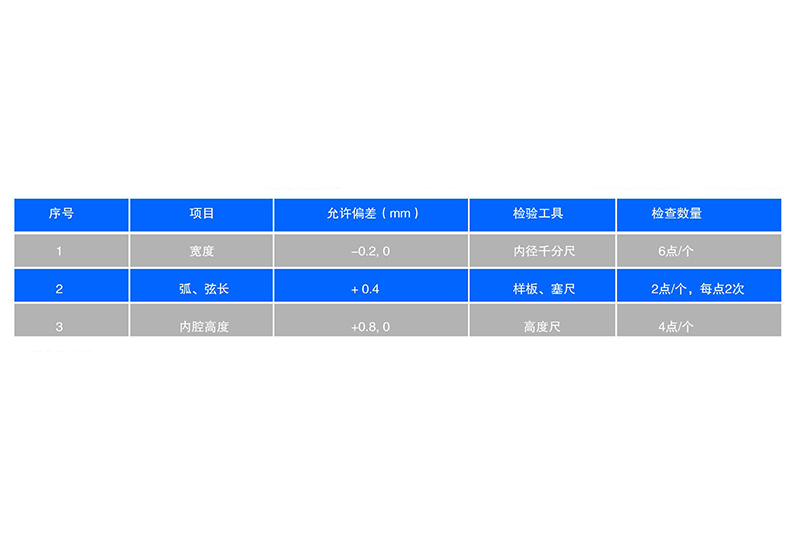

The Shield Segment Mould is adopted rolling-articulated opening and closing to ensure non-deformation after continuous production ,and non-leakage of slurry after embedded floating seals. The precision of cavity width can be controlled at ±0.2mm, and the safety protection device is designed to maximize the safety operation of employees. The shield tunnel lining segment mould is designed for the production of shield segment, compared with other types of mould, the design and manufacturing requ...

Super Purchasing for Ecological Components - Shield Segment Mould – Hicorp Group Detail:

The Shield Segment Mould is adopted rolling-articulated opening and closing to ensure non-deformation after continuous production ,and non-leakage of slurry after embedded floating seals. The precision of cavity width can be controlled at ±0.2mm,

and the safety protection device is designed to maximize the safety operation of employees. The shield tunnel lining segment mould is designed for the production of shield segment, compared with other types of mould, the design and manufacturing requirements are very strict. The quality of the formed tunnel structure is closely related to the quality of the concrete segment, and the quality of the concrete segment largely depends on the quality of the steel mould.

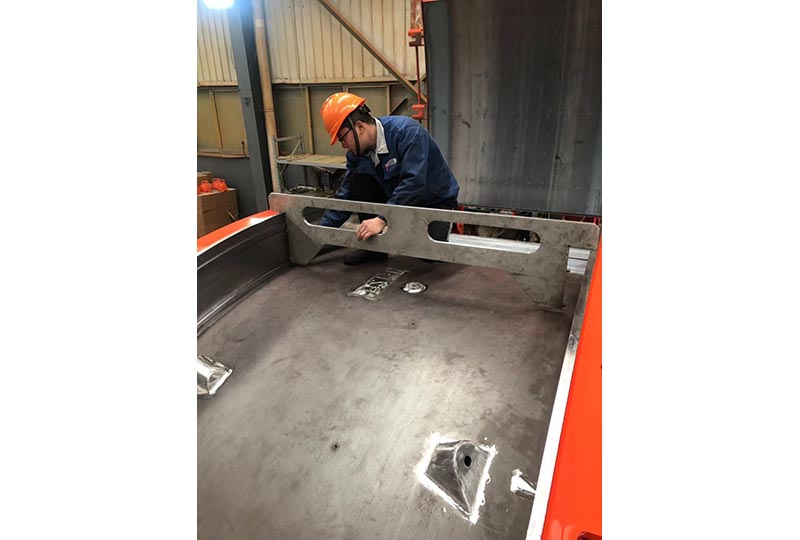

Robot Automatic Welding, Processing of Side Plate, On-site Production (Carrousel), Ready for Delivery.

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Super Purchasing for Ecological Components - Shield Segment Mould – Hicorp Group , The product will supply to all over the world, such as: Philippines, Zambia, Brunei, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.