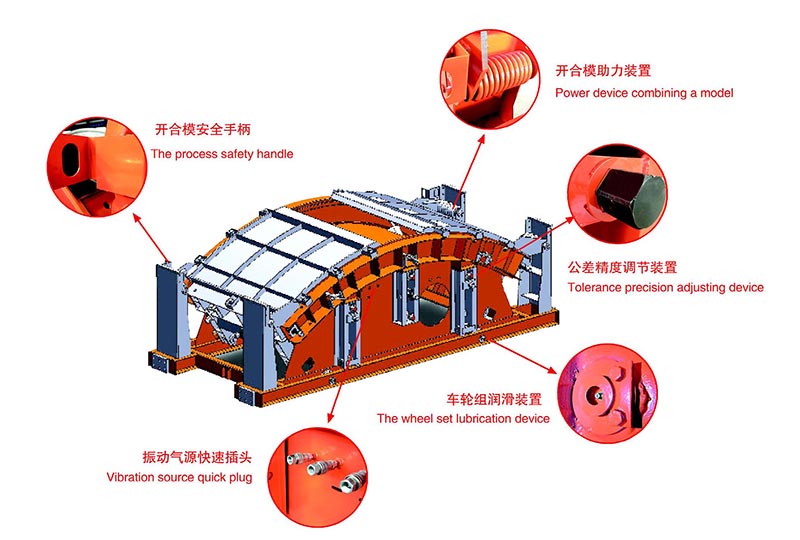

The Shield Segment Mould is adopted rolling-articulated opening and closing to ensure non-deformation after continuous production ,and non-leakage of slurry after embedded floating seals. The precision of cavity width can be controlled at ±0.2mm, and the safety protection device is designed to maximize the safety operation of employees. The shield tunnel lining segment mould is designed for the production of shield segment, compared with other types of mould, the design and manufacturing requ...

Short Lead Time for Large-Scale Tool Microscope - Shield Segment Mould – Hicorp Group Detail:

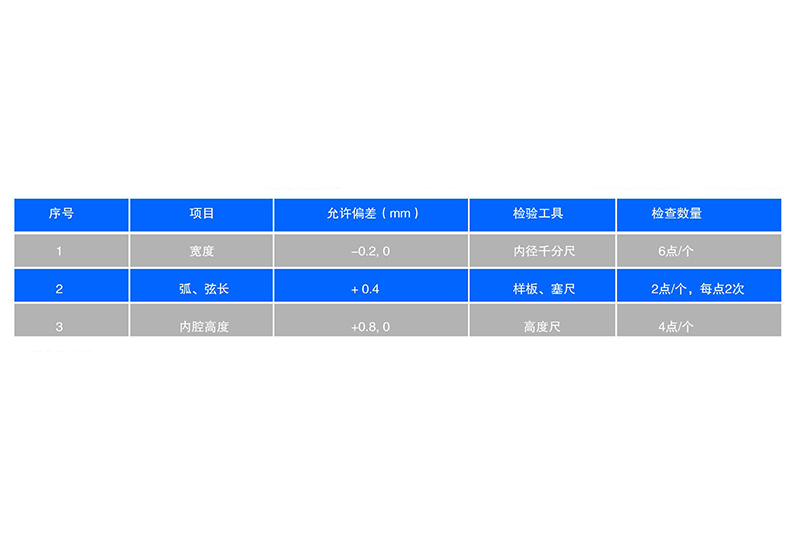

The Shield Segment Mould is adopted rolling-articulated opening and closing to ensure non-deformation after continuous production ,and non-leakage of slurry after embedded floating seals. The precision of cavity width can be controlled at ±0.2mm,

and the safety protection device is designed to maximize the safety operation of employees. The shield tunnel lining segment mould is designed for the production of shield segment, compared with other types of mould, the design and manufacturing requirements are very strict. The quality of the formed tunnel structure is closely related to the quality of the concrete segment, and the quality of the concrete segment largely depends on the quality of the steel mould.

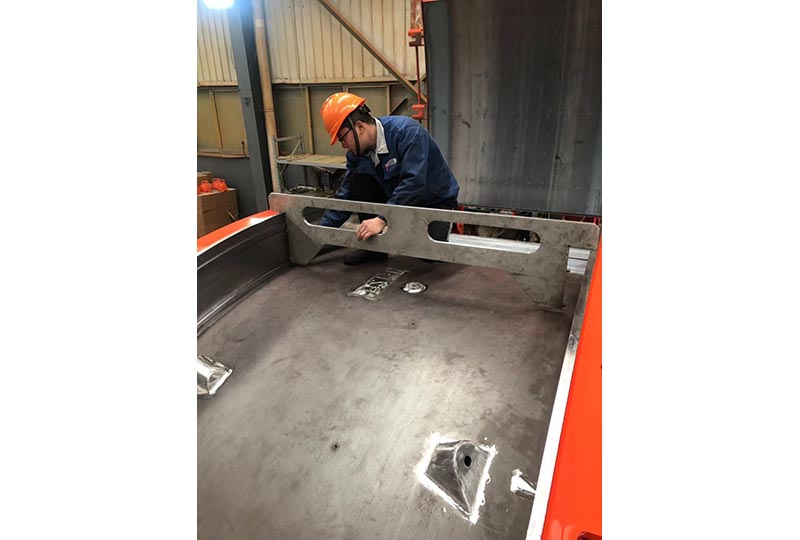

Robot Automatic Welding, Processing of Side Plate, On-site Production (Carrousel), Ready for Delivery.

Product detail pictures:

Related Product Guide:

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for Short Lead Time for Large-Scale Tool Microscope - Shield Segment Mould – Hicorp Group , The product will supply to all over the world, such as: Algeria, Iraq, Armenia, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!